Up for a challenge

Here is how I did it.

-

Step 1:

Sketch on front plane

A few dimensions

-

Step 2:

Revolve 180 reversed direction.

180 revolution will become very handy later on.

-

Step 3:

Load toolbox

from menu

Toolbox -> Configure

For how to customize thread, refer to this: https://www.youtube.com/watch?v=DKwnvsM8-xIUnder Sizes use numbers in the the last row

-

Step 4:

Under thread data use numbers in the the last row

-

Step 5:

Save and open hole wizard

Choose these settings

-

Step 6:

You should get this.

I tapped the hole so early because there are things with dimensions to the tapped point.

-

Step 7:

Sketch on right plane

All dimensions are from PDF file except Ø0.4670 is measured in CorolDRAW. Refer to my previous comment for reasons.

-

Step 8:

New sketch on right plane

Convert the line and extend it to pass the revolved body

-

Step 9:

Use this one line sketch to extrude cut

-

Step 10:

Sketch on front plane

Tangent relationship is not necessary at top but it can give me a fully defined sketch.

I recommend finish this step before you revolve the upper cylinders. Otherwise this cut intersect with them and you need to create a reference plane and do extrude cut up to surface, which is more work.

The small circle in the middle can be replaced with just a point. It is useful later.

-

Step 11:

Now you can revolve and merge and leave the center hollow.

-

Step 12:

Revolve cut the lower part

-

Step 13:

Sketch on this flat surface and the center of this circle should align with the partial circle in the sketch for revolving. That is why I put dimensions in page 2 into that sketch.

-

Step 14:

Because I revolve 180 degrees, now you can create a reference plane as pictured.

-

Step 15:

Sketch on this new plane

Convert the edge and use R0.343 from page 5

Offset 0.284 from page 3

0.1788056 from page 3 is not used anywhere. 0.27 is hard to tell from what to what.

-

Step 16:

Sketch on top face of upper cylinder

dimensions in page 4

-

Step 17:

Hole wizard as pictured

Position snaps to points in previous sketch

-

Step 18:

Revolve cut 180 use temporary axis

-

Step 19:

Pattern as pictured

-

Step 20:

Now mirror body and merge

-

Step 21:

Use the small circle in the sketch here as reference and tap a hole

-

Step 22:

Tap another hole here snap to the center of the bigger semi circle

-

Step 23:

Chamfer

-

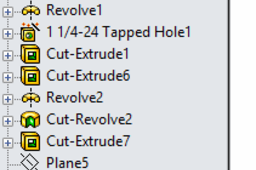

Step 24:

Finished feature tree. I do not think I can make it any shorter at the moment.

I hope this helps.